highlights

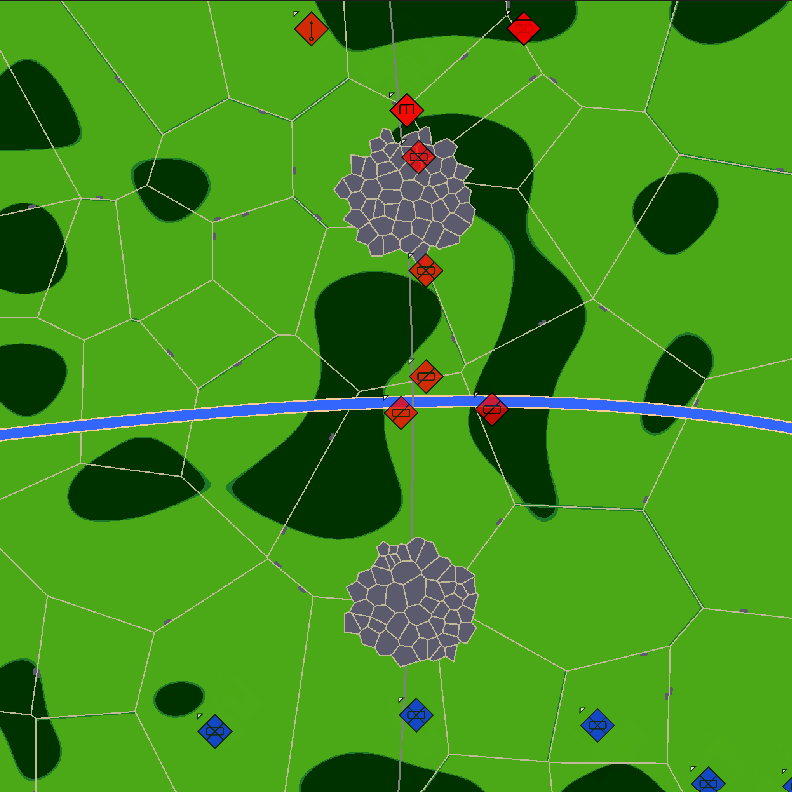

- tip/tilt range of ±2 º (optical)

- closed-loop bandwidth exceeding 1 kHz

- high-resolution, low-power, wide-range sensors

- very low power consumption (< 0.2 W) at max. tip/tilt

high-resolution, high dynamics.

The FSMs in the optical terminals of either civil or military satellites, airplanes and ground stations provide for the accurate alignment of transmitter and receiver. Their mirror (20 millimeter in diameter) is extremely flat, to prevent wavefront distortion. For the development of a compact, space-compatible FSM, we applied our optomechatronics and manufacturing expertise in close collaboration with FSO instruments. The FSM is capable of compensating high-frequency disturbances due to its highly dynamic response mechanism. It features a flexure-based design that enables high linearity and is maintenance-free.

high efficiency, low thermal distortion.

Thermal effects can induce stresses and deformations in the FSM construction. Therefore, we used high-efficiency variable-reluctance actuators, which have a higher force-to-volume and force-to-energy ratio than alternative actuator types. We applied high-resolution eddy current sensors for accurate pointing precision. Our efficient design for manufacturing purposes allows high-volume production of these FSMs.

we successfully industrialized the FSM design.

The FSM’s industrialization presented us with various challenges. We made smart material choices, optimized manufacturability and reduced costs considerably. In addition, we designed special versions of components such as an extremely efficient actuator. We put the FSMs through their paces using strict test protocols, to ensure that they survive a launch and deliver reliable, high performance. Our FSMs can be supplied in accordance with the European standards specifications.

.jpg)

.jpg)