highlights

- fully equipped 20-foot container testbed

- 80 kW thermal power, AC 170 kVA, DC 60 kW electrical power

- complete system design

- lumped-element modelling

- optimized heat-exchange loop

- system realization, test and validation

electrical power, cooling and heating.

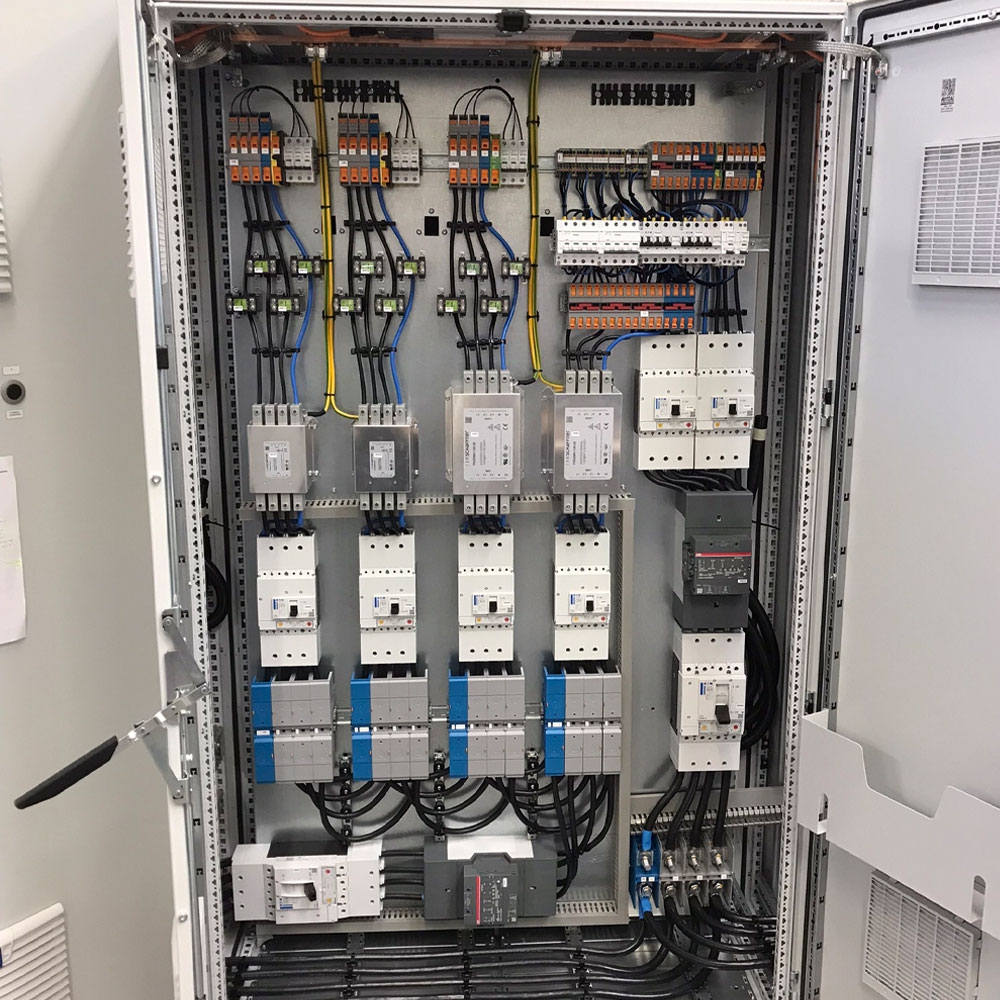

We were requested to build a system that could perform verification tests on high-power mission subsystems concerning their electrical and thermal energy specifications. This helps the MinDef act as a smart buyer, smart specifier for energy & cooling systems and drawing up specifications for – off-the-shelf as well as tailor-made – components in system designs. We created a measurement tool that can generate very high cooling or heating power using a reversible heat pump in a fully optimized heat-exchange fluid loop. Also, the system can supply and measure AC and DC electrical power. The complete testbed is housed in a 20-foot container, which facilitates field operation. It can be used to generate and measure the electrical and cooling energy supply, and test equipment to verify suppliers’ specification sheet data.

modelling and making.

For the testbed design, we drew on our extensive knowledge of thermal and fluidic systems and used our self-developed lumped-element modelling tool. This enabled us to analyze and model the thermal dynamics of the complete testbed in a very detailed way and predict the system’s behavior during the various use cases in which it will operate. We partnered with several industry partners for, for example, the mechanical container construction, including all interfaces, and a dedicated chiller design for the required tight footprint. We designed the high-power electronics and then realized, tested and validated the complete system in-house. Now, it is already used for operation in the field.

highlights

- extensive robotics and AI experience

- broad mechatronics, vision and physics expertise

- comprehensive virtual reality animation

simulation of the mission environment.

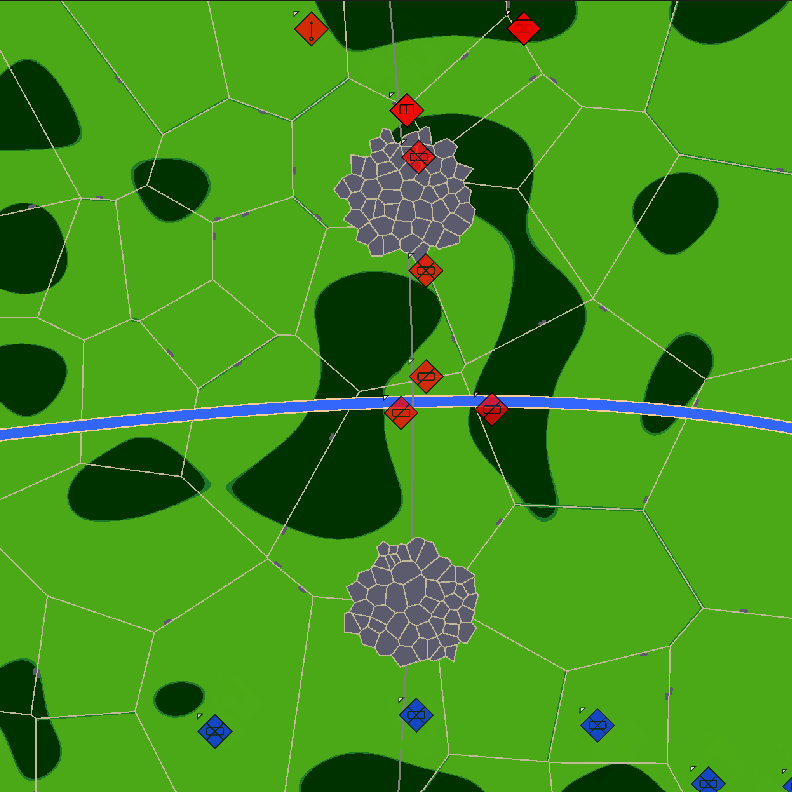

The Royal Netherlands Army, within the Robots and Autonomous Systems Project, is investigating how robots and autonomous systems can support military personnel. While a great deal of technology is currently available on the market in the field of unmanned vehicles and platforms, it often lacks the intelligence required to enable the systems to genuinely operate autonomously. We are building a simulation to investigate what happens when intelligent robots receive information (from sensors or otherwise) and are given an objective. What choices will they be making, what are the constraints they run into, how do they communicate with peer robots and – for later – how can they work together with humans?

knowledge of the real world.

We apply our broad expertise in mechatronics, robotics, vision and physics to supply knowledge of how a robot moves in the real world. We also have a great deal of experience with artificial intelligence (AI). Integrating our knowledge into a simulation enables us to test the basic functionalities, develop a feeling for the required computational power and make fundamental design choices. How do we organize communication and intelligence among robots? How does a unit consisting of robots, for example, operate? Which design parameters are decisive in actual practice?

we add value as a technology partner to the MinDef in the field of high-power energy & cooling.

The field of homeland defense is more relevant than ever. So, it is great that we can add value here. It was very satisfying to see we were able to realize a complicated system such as this testbed in a close collaboration with the MinDef and DNV. In this way, we help the MinDef to strengthen its position as a smart buyer, smart specifier in the field of high-power energy & cooling systems.

.jpg)

.jpg)

.jpg)